Sign Up to our social questions and Answers Engine to ask questions, answer people’s questions, and connect with other people.

Login to our social questions & Answers Engine to ask questions answer people’s questions & connect with other people.

Lost your password? Please enter your email address. You will receive a link and will create a new password via email.

Please briefly explain why you feel this question should be reported.

Please briefly explain why you feel this answer should be reported.

Please briefly explain why you feel this user should be reported.

How strong is Needle Punched Non-woven Fabric?

The Strength of Needle Punched Nonwoven Fabric Needle punched nonwoven fabric has emerged as a versatile material in various industries due to its impressive strength and durability. This fabric is created by mechanically interlocking fibers through a needle-punching process, resulting in a fabric tRead more

The Strength of Needle Punched Nonwoven Fabric

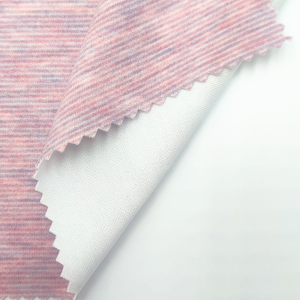

Needle punched nonwoven fabric has emerged as a versatile material in various industries due to its impressive strength and durability. This fabric is created by mechanically interlocking fibers through a needle-punching process, resulting in a fabric that exhibits unique properties tailored to specific applications. Understanding the strength characteristics of needle punched nonwoven fabric is crucial for its effective utilization in products like automotive floor mats, shoe linings, and upholstery materials.

What Is Needle Punched Nonwoven Fabric?

Needle punched nonwoven fabric is a type of nonwoven material produced by repeatedly puncturing a fiber web with barbed needles. This process entangles the fibers, creating a cohesive fabric without the need for weaving or knitting. The resulting fabric exhibits enhanced strength, dimensional stability, and versatility, making it suitable for a wide range of applications.

Factors Influencing the Strength of Needle Punched Nonwoven Fabric

Fiber Type

The choice of fiber significantly impacts the strength of needle punched nonwoven fabric. Synthetic fibers like polyester and polypropylene are commonly used due to their high tensile strength and durability. Natural fibers, such as cotton and hemp, can also be utilized, offering benefits like biodegradability and cost-effectiveness.

Fiber Length and Orientation

The length and orientation of fibers within the fabric influence its strength properties. Longer fibers and those aligned in the direction of stress can enhance tensile strength, while shorter or randomly oriented fibers may result in lower strength but increased flexibility.

Needle Penetration Density

The density of needle penetration during the manufacturing process affects the fabric’s strength. Higher needle penetration density leads to greater entanglement of fibers, resulting in a stronger and more cohesive fabric.

Fabric Weight and Thickness

Heavier and thicker needle punched nonwoven fabrics generally exhibit higher strength due to the increased amount of fiber material present. However, the specific application requirements must be considered to balance strength with other desired properties like flexibility and breathability.

Strength Properties of Needle Punched Nonwoven Fabric

Tensile Strength

Needle punched nonwoven fabrics demonstrate impressive tensile strength, making them suitable for applications that require resistance to stretching and breaking. The mechanical bonding of fibers through the needle-punching process contributes to this enhanced strength.

Tear Strength

The tear strength of needle punched nonwoven fabric is another critical property, indicating its ability to resist propagation of tears under stress. This characteristic is essential for applications subjected to abrasive conditions, such as automotive interiors and industrial filters.

Dimensional Stability

Needle punched nonwoven fabrics exhibit excellent dimensional stability, maintaining their shape and size under various environmental conditions. This stability ensures consistent performance and longevity in end-use applications.

Applications Demonstrating the Strength of Needle Punched Nonwoven Fabric

Automotive Industry

In the automotive sector, needle punched nonwoven fabrics are utilized for applications like trunk liners, headliners, and floor mats. The strength and durability of these fabrics contribute to the overall performance and longevity of vehicle interiors.

Footwear Manufacturing

Needle punched nonwoven fabric serves as a reliable material in footwear manufacturing, providing structure and support in components like insoles and shoe linings. Its strength ensures the durability and comfort of the final product.

Upholstery and Furniture

In the furniture industry, needle punched nonwoven fabrics are used in upholstery materials, offering strength and resilience in cushions, mattresses, and OEM nonwoven for sofa manufacturing components. The fabric’s durability enhances the comfort and lifespan of furniture products.

Advantages of Needle Punched Nonwoven Fabric

High Strength: Offers superior tensile and tear strength, suitable for demanding applications.

Durability: Resistant to wear and tear, ensuring long-lasting performance.

Versatility: Can be tailored to meet specific requirements in various industries.

Cost-Effectiveness: Provides a balance between performance and affordability.

Challenges and Considerations

While needle punched nonwoven fabrics offer numerous advantages, there are considerations to keep in mind:

Moisture Sensitivity: Some needle punched nonwoven fabrics may absorb moisture, potentially affecting their performance.

Limited Elasticity: The fabric’s strength may come at the expense of flexibility in certain applications.

Environmental Impact: The use of synthetic fibers raises concerns about biodegradability and environmental sustainability.

Future Trends in Needle Punched Nonwoven Fabric

The ongoing development of needle punched nonwoven fabrics focuses on enhancing their strength and performance characteristics. Advancements include the incorporation of recycled materials, improved bonding techniques, and the development of specialty fibers to meet the evolving demands of various industries.

Conclusion

Needle punched nonwoven fabric stands out for its remarkable strength and versatility, making it an invaluable material across multiple industries. Understanding the factors that influence its strength properties allows for informed decisions in material selection and application design. As technology progresses, needle punched nonwoven fabrics will continue to evolve, offering innovative solutions to meet the challenges of modern manufacturing and product development.

See lessNMN for Peak Performance: Maximize Healthspan via Resveratrol’s Anti-Aging Power

What Are the Benefits of Taking Resveratrol Capsules? Resveratrol has been studied for its antioxidant power, its ability to protect the heart and blood vessels, and its unique role in activating longevity pathways inside cells. When paired with NMN (nicotinamide mononucleotide)—another molecule knoRead more

What Are the Benefits of Taking Resveratrol Capsules?

Resveratrol has been studied for its antioxidant power, its ability to protect the heart and blood vessels, and its unique role in activating longevity pathways inside cells. When paired with NMN (nicotinamide mononucleotide)—another molecule known for boosting energy and NAD+ levels—the benefits go even further. If you are aiming for peak performance nmn resveratrol can be one of the smartest supplement strategies.

Promotes Antioxidant Activity

Every day, pollution, stress, and just getting older are daily challenges to our organism with what is called oxidative stress. By resveratrol deprives harmful free radicals and decreases inflammation, providing the cells with essential health support through this mechanism.

Supports Cardiovascular Health

Resveratrol is beneficial in safeguarding your heart and blood vessels by increasing the production of endothelial cells, which in turn, improves your blood flow.

Synergy with NMN – Enhance NAD+ for Peak Performance

When resveratrol is paired with high-quality NMN—like the best NMN powder used in Effepharm formulations—the overall efficacy is significantly enhanced. Study from the University of Washington found that combining NMN with resveratrol increased NAD+ levels in cardiac and skeletal muscle tissues by 71.5%, and upregulated SIRT2 expression by 1.72 times. These improvements play a key role in supporting cardiovascular protection, metabolic function, and anti-inflammatory repair. This is a great example of how peak performance nmn resveratrol works together at the cellular level.

What Is Resveratrol Used For?

Resveratrol is a vital functional supplement for increasing longevity, and it does so in several ways. It can help to repair DNA, promote the regeneration and repair of mitochondria, and improve the resistance to stress. Moreover, it is found that NMN, in combination with resveratrol (nicotinamide mononucleotide), can also accelerate the release of NAD+, a vital compound that, in turn, powers the production of ATP and the anti-aging activities in the cells.

This is exactly the reason why using resveratrol capsules for peak performance is a very practical supplement solution, merging resveratrol with NMN that boosts both energy to our brains, cognitive sharpness, and longevity. With this one-of-a-kind daily formula, you can become and stay vibrant and enjoy life like never before.

Who Should Not Take Resveratrol?

While resveratrol capsules are safe for most healthy adults, individuals with specific health concerns or those on medications should consult a qualified healthcare professional before use.

When to Take Resveratrol: Morning or Night?

For optimal daily results, it is recommended to take NMN and resveratrol in the morning. This timing helps you get the most out of your day—when you are likely to be at your most productive and focused. For those pursuing peak performance nmn resveratrol, morning intake aligns best with energy cycles.

Why Choose Uthever® NMN & LipoAvail™ Resveratrol?

Uthever® NMN, the world’s first clinically proven NMN brand, offering a trusted solution for those seeking proven results in healthy aging and cellular vitality. The innovative LipoAvail™ liposomal resveratrol ensuring superior absorption (14 times relative bioavailability surge) at the cellular level. Innovation and scientific evidence converge to create precise synergies that make you feel more powerful and more adaptable.

Live at Your Peak: The Smart Choice for Healthy Aging

Resveratrol capsules offer various science-based health benefits, including antioxidant support, improved metabolism, and enhanced cellular function. Their effects are amplified when combined with NMN, especially through bulk NMN and high-efficiency liposomal supplements. This synergy makes products like peak performance nmn resveratrol an excellent choice for individuals looking to promote anti-aging, boost energy, and maintain long-term health.

Interested in elevating your wellness strategy? Contact us to learn more about peak performance nmn resveratrol.

See lessHow do you use a heat press machine?

Heat press machines are essential tools for transferring designs onto various substrates like fabrics, ceramics, and metals. Whether you're customizing t-shirts, mugs, or creating personalized gifts, mastering the use of a heat press machine is crucial for achieving professional results. UnderstandiRead more

Heat press machines are essential tools for transferring designs onto various substrates like fabrics, ceramics, and metals. Whether you’re customizing t-shirts, mugs, or creating personalized gifts, mastering the use of a heat press machine is crucial for achieving professional results.

Understanding Heat Press Machines

A heat press machine applies heat and pressure to transfer a design from a transfer medium onto a substrate. The process involves precise control over temperature, time, and pressure to ensure a successful transfer. Different types of heat press machines cater to various needs:

Label Heat Press Machine: Specialized for applying labels or tags onto garments, ensuring durability and a professional finish.

Cheap Heat Press Machine: Budget-friendly options suitable for beginners or small-scale operations.

Portable Heat Press Machine: Compact and lightweight, ideal for on-the-go customization or limited workspace.

Preparing for Heat Pressing

Before operating your heat press machine, ensure you have the following:

Design: Create or select your design, ensuring it’s mirrored if necessary.

Transfer Medium: Choose the appropriate transfer paper or vinyl compatible with your design.

Substrate: Select the item you wish to transfer the design onto, such as a t-shirt, mug, or cap.

Heat Press Machine: Ensure your machine is set up correctly and is compatible with the materials you’re using.

Operating the Heat Press Machine

Setting Up the Machine

Power On: Turn on your heat press machine and allow it to reach the desired temperature.

Adjust Settings: Set the appropriate time and pressure based on the material and transfer medium.

Pre-Press: Place the substrate onto the lower platen and close the machine for a few seconds to remove wrinkles and moisture.

Positioning the Design

Place Transfer: Position the transfer paper or vinyl onto the substrate, ensuring it’s aligned correctly.

Cover: Use a protective sheet, like Teflon, to cover the design and prevent direct contact with the platen.

Pressing

Close Machine: Lower the upper platen onto the design, applying even pressure.

Monitor Time: Wait for the set time to elapse, ensuring the transfer process is complete.

Open Machine: Carefully lift the upper platen and remove the substrate.

Cool Down: Allow the item to cool before handling to set the design properly.

Troubleshooting Common Issues

Uneven Pressure: Ensure the machine’s pressure is adjusted evenly across the platen.

Incomplete Transfers: Check the temperature and time settings; increase if necessary.

Ghosting: Avoid moving the substrate during pressing to prevent blurred designs.

Maintenance Tips

Regular Cleaning: Wipe down the platens after each use to remove any residue.

Check Components: Inspect the machine periodically for wear and tear, especially the heating element and pressure system.

Storage: Store the machine in a clean, dry place to prevent damage.

Conclusion

Mastering the use of a heat press machine opens up a world of customization possibilities. Whether you’re using a Label Heat Press Machine for professional branding or a Portable Heat Press Machine for on-the-go projects, understanding the fundamentals ensures quality results. Always refer to your machine’s manual for specific instructions and settings tailored to your equipment.

See lesswhat is food grinder machine?

What is a Food Grinder Machine? A food grinder machine is a device that allows you to grind or mince food into smaller pieces. The machine uses rotating blades or plates that slice through the food, breaking it down into finely or coarsely ground textures. Food grinders are commonly used in both homRead more

What is a Food Grinder Machine?

A food grinder machine is a device that allows you to grind or mince food into smaller pieces. The machine uses rotating blades or plates that slice through the food, breaking it down into finely or coarsely ground textures. Food grinders are commonly used in both home kitchens and commercial kitchens to prepare ingredients like meat, vegetables, nuts, and grains.

Key Components of a Food Grinder Machine

Motor: Powers the grinding mechanism and determines the machine’s efficiency.

Grinding Plates: These are the metal or stainless steel plates with holes of varying sizes, which control the texture of the grind.

Feeding Tube: This is where food is inserted into the machine for grinding.

Blades: The blades help to cut and mince the food, working in conjunction with the grinding plates.

On/Off Switch: Most food grinder machines have simple buttons for ease of use.

Types of Food Grinder Machines

Food grinder machines come in different varieties, each designed for specific tasks. Let’s explore the most common types:

1. Electric Food Grinder Machines

Electric food grinder machines are powered by electricity and are the most efficient and widely used. They are capable of handling large quantities of food quickly and with minimal effort. These machines often feature various attachments, including different grinding plates, to allow for versatility in food processing.

Key Features:

Faster and more efficient

Larger capacity for grinding

Multiple attachments for different grinding needs

Common Uses:

Grinding meat for sausages or burgers

Grinding vegetables for soups or baby food

Grinding nuts and grains for baking

2. Manual Food Grinder Machines

Manual food grinders require physical effort to operate, as they are powered by hand rather than electricity. They are usually more compact and affordable, making them ideal for occasional use in small kitchens.

Key Features:

Requires manual labor to operate

Smaller and more portable

Ideal for small batches

Common Uses:

Grinding small amounts of meat

Grinding vegetables for homemade dips

Grinding spices and herbs for fresh flavors

3. Meat Grinder Machines

Meat grinder machines are specialized food grinders designed primarily for grinding meat. These machines usually come with additional features such as more powerful motors, larger feeding tubes, and stronger blades to handle tougher cuts of meat.

Key Features:

Stronger motor and more durable parts

Larger capacity for grinding tough meats

Can often grind bones for pet food

Common Uses:

Grinding meat for sausages and ground beef

Preparing meat-based fillings for pastries

Making pet food from raw meat and bones

How Does a Food Grinder Machine Work?

Food grinders operate on a simple principle: food is placed into the feeding tube, where it is crushed by rotating blades and forced through the grinding plate, producing ground food. The speed at which food is ground depends on the power of the motor (in electric grinders) or the amount of force applied (in manual grinders).

Step-by-Step Process

Insert Food: Place the food into the feeding tube.

Grinding: Turn on the motor or turn the handle in manual grinders. The blades will cut the food into small pieces.

Pass Through Plates: The food is forced through the grinding plate, which determines the size of the ground food.

Collect Ground Food: The ground food exits through the plate holes and is collected into a container or bowl.

Important Considerations:

Blade Quality: Sharp, high-quality blades ensure efficient and clean grinding.

Plate Size: The size of the holes in the grinding plate determines the texture of the ground food. Smaller holes produce finer grinds, while larger holes give a coarser texture.

Benefits of Using a Food Grinder Machine

Using a food grinder machine offers numerous benefits, especially when preparing ingredients from scratch. Let’s take a closer look at the key advantages:

1. Customizable Grind Sizes

Whether you need finely ground meat for patties or coarse ground vegetables for stews, a food grinder machine can help you achieve the desired texture. With different grinding plates, you have full control over the size of your grinds.

2. Freshness and Flavor

Grinding your own food allows you to enjoy fresher ingredients without preservatives or additives. Whether it’s fresh meat for burgers or homemade baby food, using a food grinder machine ensures superior taste and quality.

3. Time-Saving

An electric food grinder machine can grind large quantities of food in a short amount of time. It saves the time and effort required for manual chopping, making meal preparation faster and more efficient.

4. Versatility in Food Preparation

Food grinder machines are versatile and can be used for a wide range of tasks beyond just meat grinding. You can use them for vegetables, fruits, nuts, and even spices, giving you more options in the kitchen.

Things to Consider When Buying a Food Grinder Machine

When shopping for a food grinder machine, consider the following factors to ensure you choose the right one for your needs.

1. Power and Motor Strength

If you plan to grind tough ingredients like meat or bones, ensure the machine has a strong motor that can handle the workload. For smaller tasks, a manual grinder may be sufficient.

2. Ease of Cleaning

Grinders can accumulate food residue, so choose a machine that’s easy to disassemble and clean. Stainless steel models are often the easiest to clean and maintain.

3. Capacity and Size

Consider how much food you plan to grind at once. Larger models with bigger feeding tubes are ideal for high-volume grinding, while smaller models may be better for casual use.

4. Attachments and Versatility

Some food grinder machines come with additional attachments, such as sausage stuffers, which add versatility to the appliance. Check if the machine offers different plate sizes or other attachments for a broader range of uses.

Conclusion: Why Invest in a Food Grinder Machine?

A food grinder machine is a must-have appliance for any kitchen. It offers a convenient way to grind ingredients quickly and efficiently, providing you with fresh, flavorful meals. Whether you’re looking to make homemade sausages, grind vegetables for soups, or create your own nut butter, a food grinder machine simplifies food preparation and enhances your cooking experience.

See lessWhat type of instrument is a harmonica?

What Is a Harmonica? A harmonica instrument, specifically a free reed instrument. It consists of a set of chambers, each containing reeds that vibrate when air is blown or drawn through the instrument. The sound produced by the harmonica is unique, with each reed producing a different pitch. DespiteRead more

What Is a Harmonica?

A harmonica instrument, specifically a free reed instrument. It consists of a set of chambers, each containing reeds that vibrate when air is blown or drawn through the instrument. The sound produced by the harmonica is unique, with each reed producing a different pitch. Despite its small size, the harmonica can produce a variety of musical tones, from deep and soulful to bright and playful.

Key Features of the Harmonica

Portable: The harmonica is small and easy to carry, making it a popular choice for musicians on the go.

Simple Design: It is composed of a metal comb with a series of holes, each containing a reed that creates sound when air passes through.

Expressive: The player can bend the notes, creating a wide range of expressive sounds.

The Structure of a Harmonica

A harmonica typically consists of several parts that work together to produce sound. These include the comb, reeds, cover plates, and the mouthpiece.

1. Comb

The comb is the main body of the harmonica and is typically made from wood, plastic, or metal. It has holes cut into it where the reeds are placed. The comb also helps to amplify the sound produced by the reeds.

2. Reeds

Each hole in the harmonica comb contains a metal reed that vibrates when air passes through it. The reed is secured at one end and free at the other, and it is tuned to a specific pitch. When a player blows or draws air through a hole, the reed vibrates, producing sound.

3. Cover Plates

The cover plates are located on the top of the harmonica and protect the reeds. They are often made of metal and help project the sound. The cover plates are designed to amplify the harmonica’s voice and make it easier to hear when played.

4. Mouthpiece

The mouthpiece is where the player blows or draws air into the instrument. It is often designed for comfort and provides easy access to all the holes in the harmonica.

Types of Harmonicas

There are several different types of harmonicas, each with a unique purpose and sound. Below are the most common types.

1. Diatonic Harmonica

The diatonic harmonica is the most popular and widely used type. It’s designed to play in one key, typically the major scale. This harmonica is most commonly used in blues, rock, and folk music. It’s known for its rich, soulful sound and its ability to produce bends, which gives it an expressive quality.

Key Characteristics: 10 holes, diatonic scale (7 notes per octave)

Common Uses: Blues, rock, folk music

2. Chromatic Harmonica

The chromatic harmonica is designed to play all the notes in the chromatic scale, allowing for a broader range of musical expression. This type of harmonica is equipped with a button-activated slide mechanism that shifts the pitch, enabling the player to play in any key.

Key Characteristics: 12 to 16 holes, slide button, chromatic scale

Common Uses: Jazz, classical, pop music

3. Tremolo Harmonica

The tremolo harmonica produces a wavering sound by having two reeds per note, one slightly sharp and the other slightly flat. This creates a rich, echo-like effect, and the instrument is often used in traditional Asian, Latin American, and European music.

Key Characteristics: Double reeds per note, distinctive tremolo effect

Common Uses: Traditional, folk, and world music

4. Orchestral Harmonica

An orchestral harmonica is often used in large musical compositions or classical music pieces. It’s typically played in orchestras or used by soloists and is tuned to create specific musical intervals.

Key Characteristics: Larger, tuned for orchestral performance

Common Uses: Classical, orchestral music

5. Bass Harmonica

Bass harmonicas are larger in size and designed to play lower-pitched notes. They are typically used in harmony with other types of harmonicas or instruments in a group setting.

Key Characteristics: Larger size, low-pitched reeds

Common Uses: Group harmonica ensembles, accompaniment

How to Play the Harmonica?

Playing the harmonica is relatively simple, but mastering the instrument requires practice. Here are the basic techniques:

1. Blowing and Drawing

The most basic technique involves blowing air into or drawing air through the holes. Each hole corresponds to a different note. The diatonic harmonica, for example, allows players to create a melody by alternating between blowing and drawing.

2. Bending Notes

One of the most expressive techniques in harmonica playing is bending notes. This involves altering the pitch of the note by adjusting the airflow and tongue position. Bending is essential for playing the blues and other genres that require emotion and nuance.

3. Tongue Blocking

Tongue blocking is a technique where the player blocks certain holes with their tongue while allowing air to pass through others. This allows for playing chords or creating a more percussive sound.

Popular Uses of the Harmonica

The harmonica is used in a wide range of musical styles. Its portability and expressive sound make it an ideal instrument for many different genres.

1. Blues

The harmonica is perhaps most famous for its use in blues music. Its ability to bend notes and create a soulful sound makes it an integral part of blues bands. Many legendary blues musicians, such as Little Walter and Sonny Boy Williamson, are known for their harmonica playing.

2. Rock

In rock music, the harmonica has been used by artists like Bob Dylan, Neil Young, and The Rolling Stones. The instrument’s raw sound adds a unique layer to rock songs, whether it’s a quick solo or a steady rhythm.

3. Folk and Country

The harmonica is also commonly used in folk and country music. Its simple, natural sound fits well with acoustic instruments, adding texture and feeling to the music.

Conclusion: The Harmonica’s Role in Music

The harmonica is a versatile and expressive instrument that has become a staple in many musical genres. Whether you’re interested in playing a harmonica set for personal enjoyment or looking to explore its use in a professional setting, this small but mighty instrument offers endless possibilities. From diatonic to chromatic and tremolo harmonicas, each type serves a different purpose, giving musicians the flexibility to choose the right instrument for their musical style.

By understanding the different types of harmonicas and how to play them, you can unlock the full potential of this unique instrument. Whether you’re a beginner or an experienced player, the harmonica offers a world of musical expression just waiting to be explored.

See lessWhat makes rayon fabric stretchy compared to other materials?

Ultratex’s Revolutionary Stretchy Rayon Fabric Collection Ultratex, a leading innovator in textile manufacturing, is setting new standards for comfort, flexibility, and durability in fabric production with the launch of its cutting-edge rayon fabric stretchy collection. With an emphasis on high-perfRead more

Ultratex’s Revolutionary Stretchy Rayon Fabric Collection

Ultratex, a leading innovator in textile manufacturing, is setting new standards for comfort, flexibility, and durability in fabric production with the launch of its cutting-edge rayon fabric stretchy collection. With an emphasis on high-performance materials, Ultratex combines modern technology with natural fibers to create fabrics that meet the needs of today’s dynamic fashion and activewear industries.

What is Rayon and How Is It Made Stretchy?

Rayon has long been a popular fabric choice due to its soft, smooth texture and elegant drape. However, is rayon a stretchy material? Traditional rayon, while known for its luxurious feel and breathability, lacks the natural elasticity needed for activewear and other flexible applications. Ultratex has overcome this limitation by blending rayon with spandex or other stretch fibers, resulting in a fabric that offers added stretch while retaining the comfort and drape of traditional rayon.

This stretch is especially important in modern clothing, where movement, comfort, and fit are top priorities. By incorporating spandex or similar fibers, Ultratex’s rayon fabrics stretch with the body, providing greater freedom of movement, while maintaining the softness and elegance that rayon is known for.

95 Rayon and 5 Spandex: The Perfect Blend

A standout in Ultratex’s new collection is the 95 rayon and 5 spandex blend. This combination strikes the perfect balance between the natural elegance of rayon and the performance-enhancing stretch of spandex. The 95 rayon and 5 spandex blend is particularly popular for garments that need a little extra give, such as leggings, activewear, and form-fitting dresses.

This blend is ideal for achieving a snug, comfortable fit without compromising on breathability. The rayon provides a silky smooth texture, while the spandex ensures the fabric moves with the wearer, recovering its shape after every stretch. This fabric blend is perfect for creating clothing that not only looks good but feels great to wear.

Rayon Cotton Blend Fabric: Combining the Best of Both Worlds

Ultratex’s innovative approach doesn’t stop at 95 rayon and 5 spandex blends. The company also offers a versatile rayon cotton blend fabric that combines the softness and breathability of cotton with the luxurious drape and sheen of rayon. This blend creates a fabric that is comfortable, durable, and suitable for a wide range of fashion and home textiles.

Rayon cotton blend fabric is perfect for everyday wear, offering a light and breathable texture that’s great for warmer climates or layering in cooler months. The cotton adds comfort, while the rayon gives the fabric an elegant finish. This blend is ideal for casual and semi-formal garments, offering both durability and style.

The Advantages of Ultratex’s Stretchy Fabrics

Ultratex’s rayon fabric stretchy collection offers several key advantages over traditional fabrics:

Comfort and Fit

The stretchable nature of the fabric ensures a perfect, body-hugging fit, enhancing comfort without restricting movement.

Durability

Despite its softness, Ultratex’s stretchy rayon fabrics are durable, standing up to daily wear and machine washing.

Breathability

Both the rayon cotton blend fabric and the 95 rayon and 5 spandex fabrics maintain excellent breathability, making them ideal for warm weather and active environments.

Versatility

From athleisure to everyday wear, Ultratex’s fabrics are perfect for a wide range of clothing, including tight-fitting yoga pants and loose, flowing summer dresses.

Sustainability

Ultratex is committed to sustainable textile practices, ensuring that all their fabric blends are produced with minimal environmental impact.

A Vision for the Future of Fashion Fabrics

With the increasing demand for functional yet stylish fabrics, Ultratex is leading the way in the textile industry’s evolution. The company is focused not only on aesthetics and comfort but also on creating fabrics that enhance the wearer’s performance. Whether for casual wear, athleisure, or formal attire, Ultratex’s innovative blends of rayon fabric stretchy, 95 rayon and 5 spandex, and rayon cotton blend fabric are setting new standards for the next generation of fashion and activewear.

About Ultratex

Ultratex is a forward-thinking textile manufacturer specializing in high-performance fabrics. With a focus on innovation and sustainability, Ultratex creates versatile, durable, and comfortable fabrics for fashion, activewear, and home textiles. The company is dedicated to providing high-quality textile solutions that meet the diverse needs of today’s market.

See less